Service Equipments

Fabrication

TYPE OF WELDING

Arc Welding

Arc Welding

Generally known as stick or arc welding. Arc welding is the most basic of all welding types, is easy to master in a home welding situation.

Stick welding can be used for manufacturing, construction and repairs, very much well suited for heavy metal size 4 millimetres upwards. Thinner sheet metals and alloys are usually more suited to the mig welding types.

Argon Welding

Argon Welding

Gas tungsten arc welding (GTAW), also known as tungsten inert gas (TIG) welding, is an arc welding process that uses a non-consumable tungsten electrode to produce the weld. The weld area is protected from atmospheric contamination by an inert shielding gas (argon or helium), and a filler metal is normally used, though some welds, known as autogenous welds, do not require it. A constant-current welding power supply produces electrical energy, which is conducted across the arc through a column of highly ionized gas and metal vapors known as a plasma.

MIG Welding

MIG Welding

More commonly called MIG welding this welding type is the most widely used and perhaps the most easily mastered type of welding for industry and home use. The GMAW process is suitable for fusing mild steel, stainless-steel as well as aluminium.

Gas Welding

Gas Welding

Not used as widely for general welding of mild steel. Consists of mixing oxygen and acetylene gas to greate a flame capable of melting steels. Mostly used today for maintenance work and gas metal cutting. Also common for brazing softer metals such as copper and bronze. Can also be used for welding delicate aluminium parts such as refrigeration pipes.

Safety facility in our workshop

Safety is our first priority: While productivity, cost and customer service are core business values, we will not compromise safety for their sake. Our core safety values are: bodily injury prevention, protection of others through self-awareness & environmental cleanliness.

Safety Belt

Safety Shoze

Suit

Ffall Arrest

Ear Plug

Face Sealed

Fire Cylinder

Safey Helmate

Glows

Safety Glass

Firstaid Box

Jackat

Cone

Safety Tap

Safety Shoes

Note: Arrange safety as per work requirement

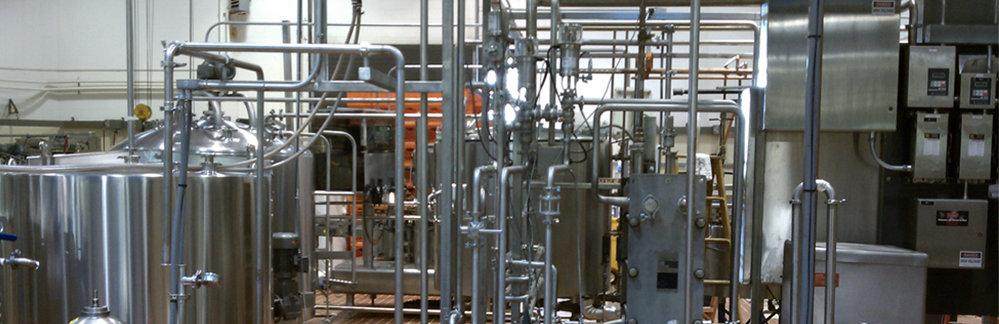

Workshop facility

Gas / Plasma

Cutter Machine

Lathe

Machine

Shaping

Machine

Drilling

Machine

Hexo

Machine

Pipe Cutting

Machine

Electric Panel

3PH / 1 PH

measurement equipment

Digital

Vernier

Dial

Vernier

Height

Gauge

Depth

Gauge

Micro Meter

Borgauge